Revolving Centre

Revolving Centre Dead Centre

Dead Centre Roller Cage

Roller Cage The depth control of the centre drill is of great importance for components going for copy turning or for auto cycle cylindrical grinding, since the location of these components is decided by the depth of the centre drill. In case of special centering & facing machine this done automatically by stoppers, but for centre lathe being used for this operation precise control of centre drill depth is difficult.

The depth control of the centre drill is of great importance for components going for copy turning or for auto cycle cylindrical grinding, since the location of these components is decided by the depth of the centre drill. In case of special centering & facing machine this done automatically by stoppers, but for centre lathe being used for this operation precise control of centre drill depth is difficult.

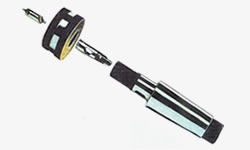

We have developed a holder which can control the depth of centre drill very precisely, with fine adjustment for setting & locking. The initial clamping of job at any axial position will not affect the depth of the centre drill. As soon as the preset depth is achieved the face of the holder touches the job face and starts rotating in the bearing & prevents further penetration of the centre drill. This is very useful for the manufacturers for Forged/Bar Shafts for precise centering operation.

The contraction of Holder is mainly like a Revolving Centre but with thrust bearing and centre drill driver to hold the centre drill, once the depth is preset it can be locked at position which gives precise reputability of operation. The body is made out of case hardened Alloy Steel, to 55-60 HRC. Rotating part is made out of case hardened alloy steel hardened 60 – 62 HRC. Standard Centre Drill driver is used to hold centre drill, which are easily available. Centre Drill Depth Control holders are available in Taper Shank from MT – 2 to MT – 4.